How to detect a rotor imbalance

Why is rotor balance important?

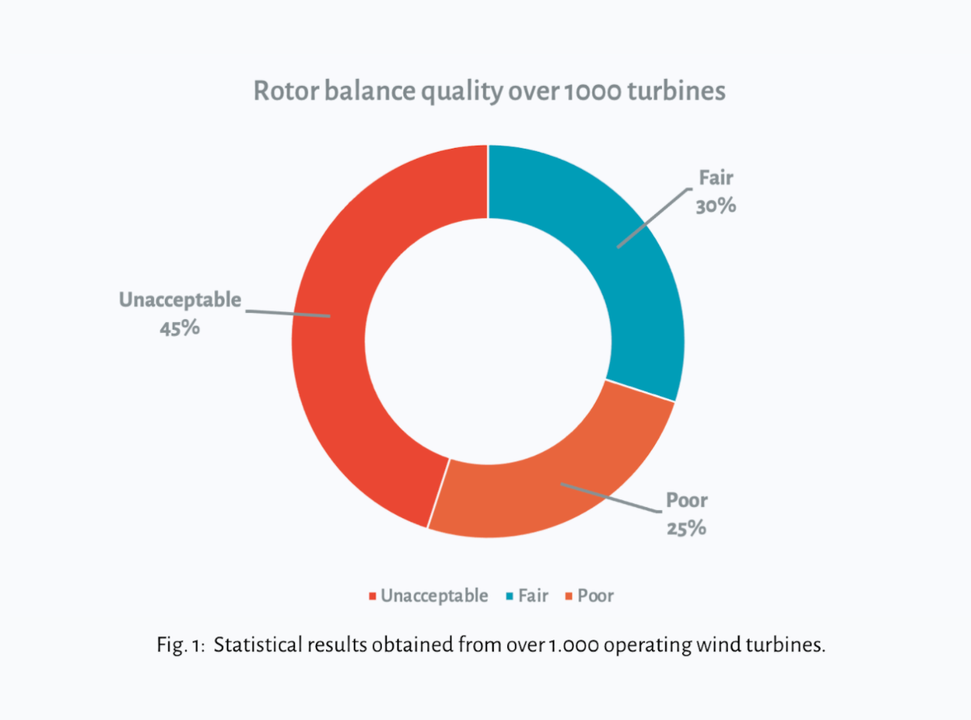

The rotor blades are one of the key components (if not the most important) of wind turbines to convert kinetic wind energy into electricity. The blades are highly loaded components, with most of these loads being transferred to the rest of the turbine components. These, however, can become excessive for the turbine if the rotor suffers from a poor balance quality. Additionally, an imbalanced rotor can reduce the power output from a wind turbine. Industry numbers collected by BerlinWind suggest that 45% of wind turbines present inadmissible rotor imbalance levels.

What are the causes and consequences of rotor imbalances?

To explain what a rotor balance is, it is important first to understand how it originates: there are two types of imbalance.

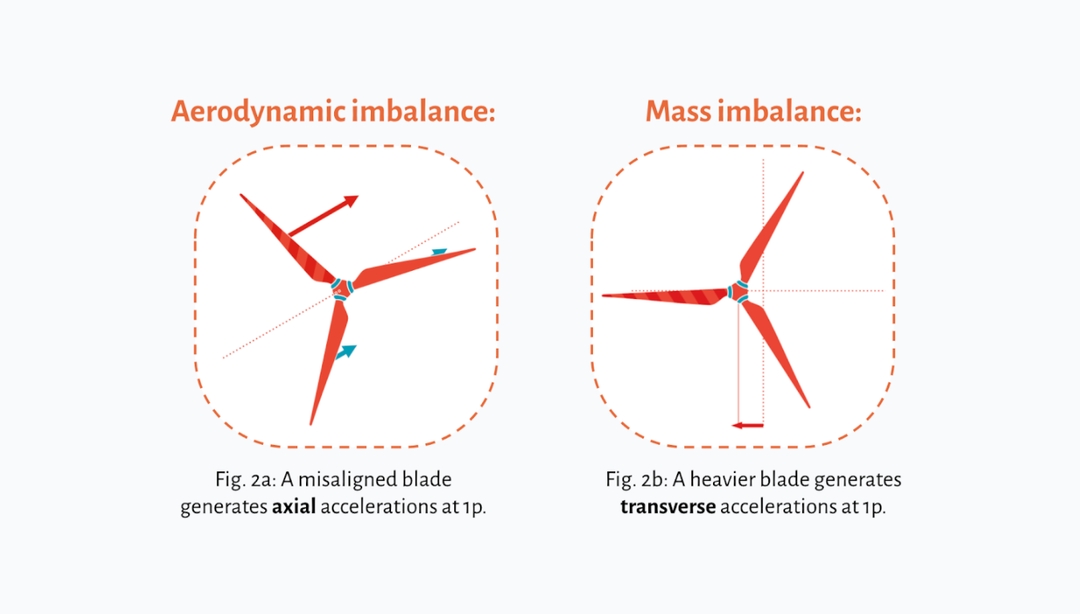

An aerodynamic imbalance occurs when one or more of the blades have a different aerodynamic efficiency than the others. This can be caused by different aerodynamic profiles between the blades, the presence of leading edge erosion, or, like in most cases, due to a blade angle deviation from its optimum position. The consequences of an aerodynamic imbalance are an increase in vibrations together with a reduction in power output, as the rotor blades are less efficient in capturing the energy from the wind.

The second type of rotor imbalance is the mass imbalance. This occurs when one of the blades is lighter or heavier than the others. When that occurs, the centre of mass of the rotor does not match with the center of rotation, leading to a significant increase in vibrations that can be harmful to the rest of the turbine, in particular the drive train, main bearing and gearbox. A mass imbalance does not cause a direct loss of production, but the effects of an increased loading on the drive train can reduce the lifetime of a wind turbine (thereof reducing its lifetime revenues).

How does Windfit® measures rotor imbalance?

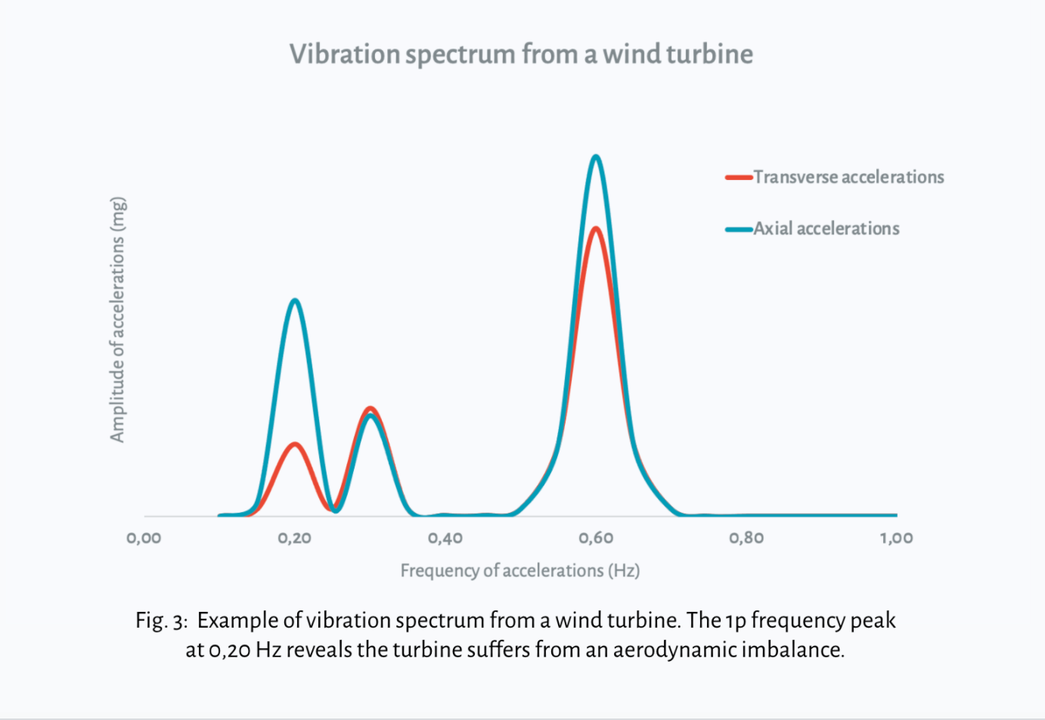

Windfit® collects high frequency acceleration data (up to 100 Hz) to capture all the vibrations that the turbine suffers. Having such a large amount of data allows it to identify what the different vibration levels are at particular frequencies, like when one of the blades passes in front of the tower, the natural oscillations of the tower, but as well the accelerations generated by only one of the blades (figure 3). If one of the blades has a different vibration behaviour than the other 2, means that this blade is unbalanced. The imbalance will either be aerodynamic or mass depending on the direction of the measured accelerations (figure 2).

Using high frequency vibration data shows how issues that are hidden to the SCADA system can be identified, monitored and corrected in a fast and precise way. Windfit® is continuously monitoring the performance of your assets so that they are optimised to maximum performance and longest lifetime. If you want to know more on how Windfit® can help you detect a rotor imbalance, have a look at our Wind Turbine Rotor Monitoring Whitepaper here.

You can also contact us to know more about how rotor imbalance issues can affect performance on your wind turbines fleet.