With rapid advances in wind turbine technology over the past decade, we wanted to see how those improvements translate into real-world performance. To do this, we compared two groups of 100 turbines: one representing the “2 MW generation” and the other the “4 MW generation,” both with sufficient operational history to draw meaningful insights.

Our dataset includes turbines from major OEMs such as Nordex, Vestas, Enercon, Senvion, SGRE, and GE. Through close collaboration with operators using Windfit, we’ve uncovered clear trends in the challenges these turbines face, the level of maintenance they require, and the tangible performance improvements that newer models deliver.

Here’s what the data tells us:

By comparing these two fleets under similar operating conditions, we learned not only how maintenance demands have shifted but also how efficiency gains, reliability, and component longevity differ between the 2 MW and 4 MW models.

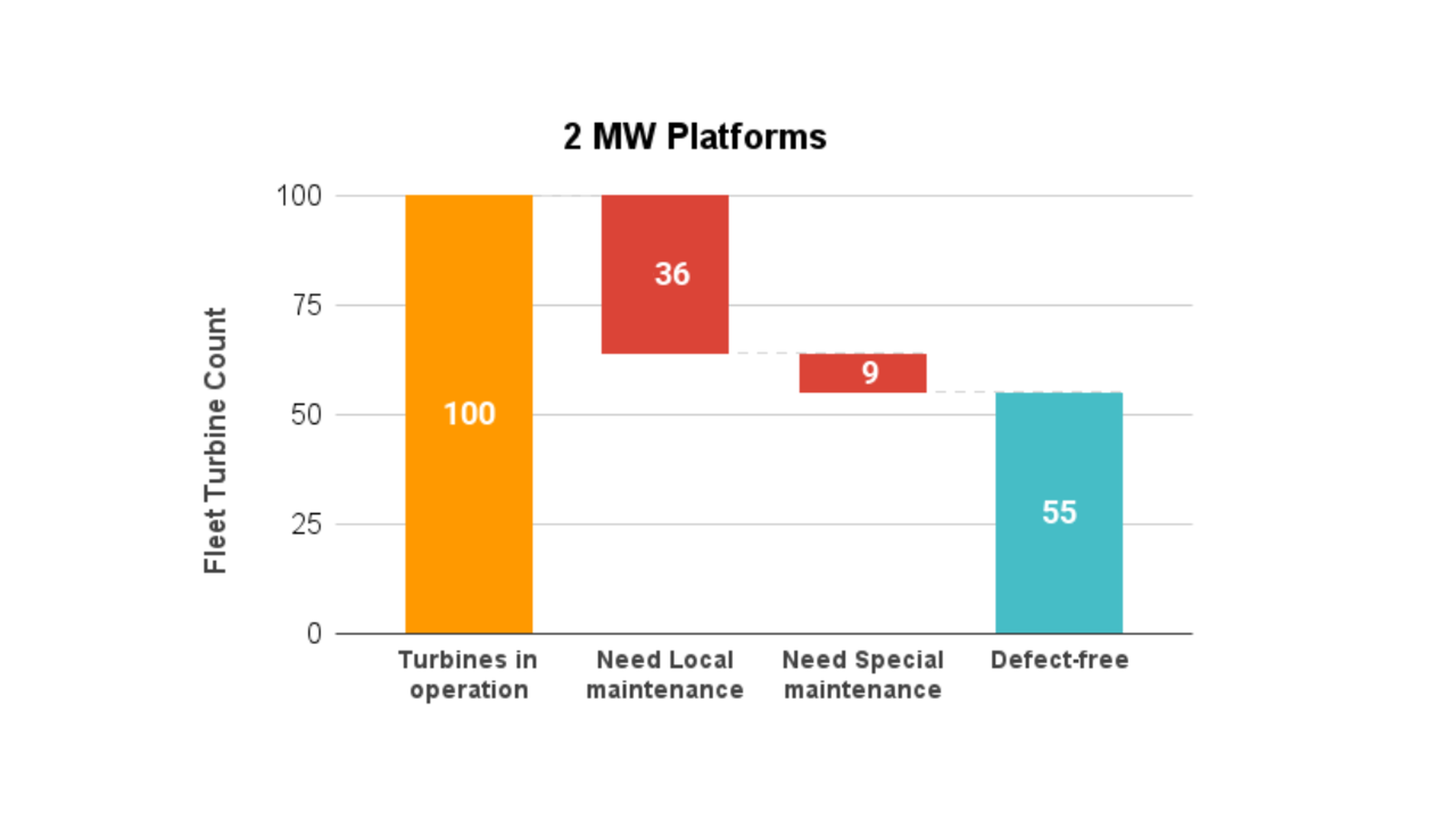

2 MW Turbines – The 2000s Era Workhorses

Types of Issues

45 out of 100 turbines flagged maintenance or performance concerns:

36 were solvable by local teams with level 1–2 maintenance, including: Resetting a controller, readjusting a setpoint, and replacing minor components.

9 required level 3 maintenance and specialized teams, such as: Blade repairs, pitch motor replacements, and pitch cylinder work.

What to Expect?

Roughly 3,500 MWh/year across a 100-turbine fleet based on restoring the performance thanks to the corrections.

Beyond energy output, reducing vibrations, wear, and tear also helps extend the remaining useful life of critical components—drive train elements, pitch bearings, main bearings, and sometimes even the nacelle frame.

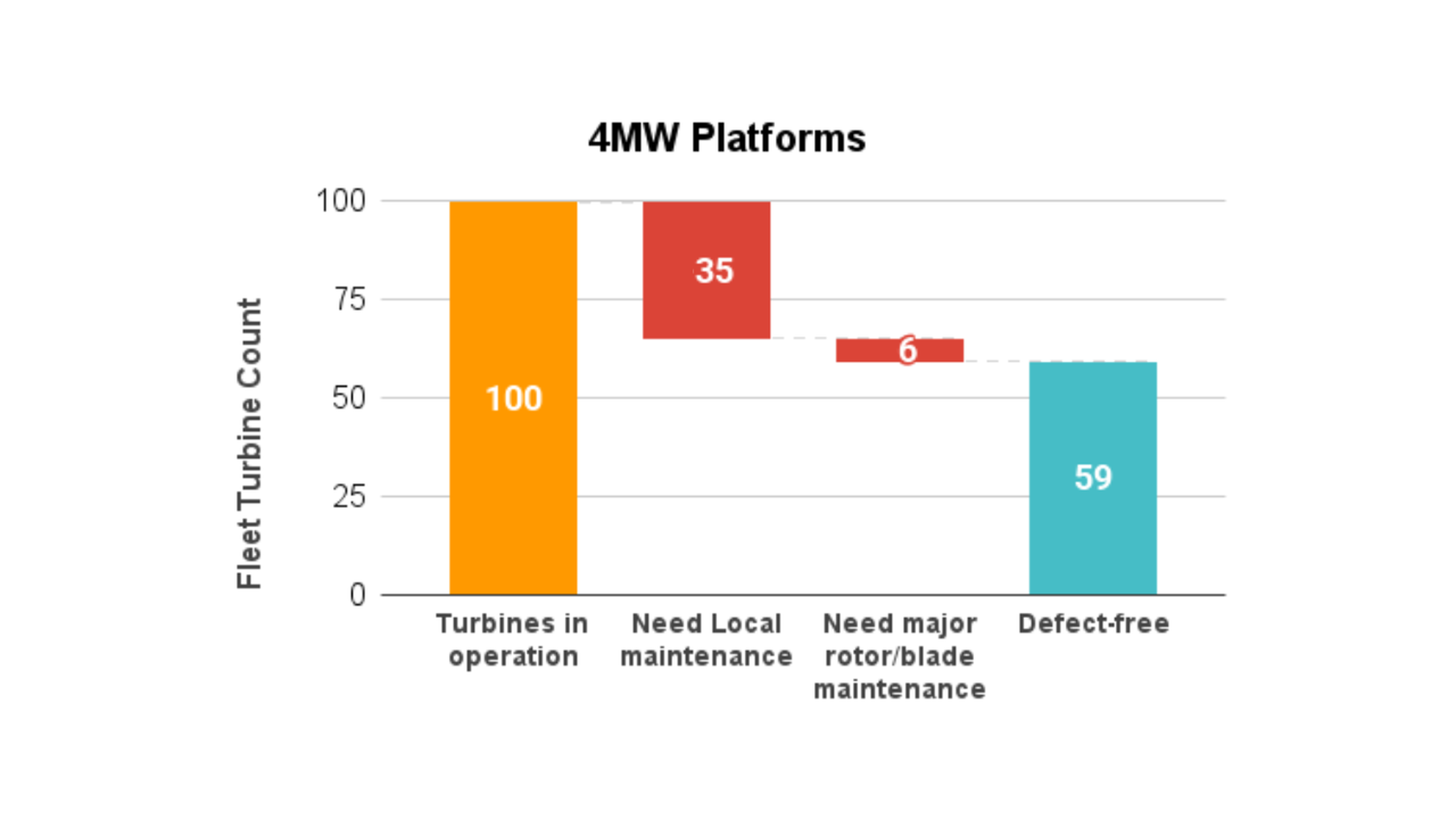

4 MW Turbines – The 2010s Era Performers

Types of Issues

41 out of 100 turbines flagged maintenance or performance concerns:

35 were solvable by local teams with level 1–2 maintenance, mainly through resetting setpoints or recalibrating control loops.

6 were linked to manufacturing or installation errors, such as:

- Mixing up blade batches

- Blade cracks due to quality control issues

- Major mass imbalances from manufacturing defects

These complex cases demand level 3–4 maintenance and close collaboration with OEMs to verify warranty coverage—a process that can be both time-consuming and high-stakes

What to Expect?

Roughly 5000 MWh per year for a fleet of 100 turbines based on improvement in the settings of turbines and better adaptation to the local wind conditions.

Thanks to remote actions and field-level electronic offsets, correction times are typically faster than with 2 MW machines.

Over the long term, this capability brings significant advantages: early detection and correction of underlying issues help prevent costly downtime, avoid major repairs, and reduce the risk of premature component replacements.

The Bigger Picture

The data highlights a clear takeaway: the latest-generation 4MW turbines present similar statistics as their 2MW predecessors, but the stakes are different:

2 MW turbines: Possess real potential for performance gains per correction and benefit significantly from lifetime-extending interventions.

4 MW turbines: Allow for faster fixes, smarter monitoring, and stronger safeguards against major failures except for rotor and blade related issues.

Let's Connect

At Sereema, we love sharing what we’ve learned from years of hands-on experience in wind turbine performance optimization. Whether you’re managing legacy 2 MW fleets or modern 4 MW models, our team is always eager to exchange insights and help you get the most out of your assets.

📩 Reach out to us — we’d be happy to share our experience and explore how Windfit can support your performance goals.

.

Sereema Team