Offshore wind is steadily growing, with more than 20 GW installed in Europe alone. Climate change is accelerating the need for swift transition to renewables as well, and the European Commission agrees.

The ambitious target to achieve 450 GW by 2050 in order to keep temperature rises below 1.5°C is pushing offshore wind farms to the front of the line in order to meet the demand.

But how can we make sure that offshore windfarms aren’t just available but operating optimally? In an industry where physical asset monitoring is tough; where performance monitoring and remote optimisation are paramount, Windfit delivers!

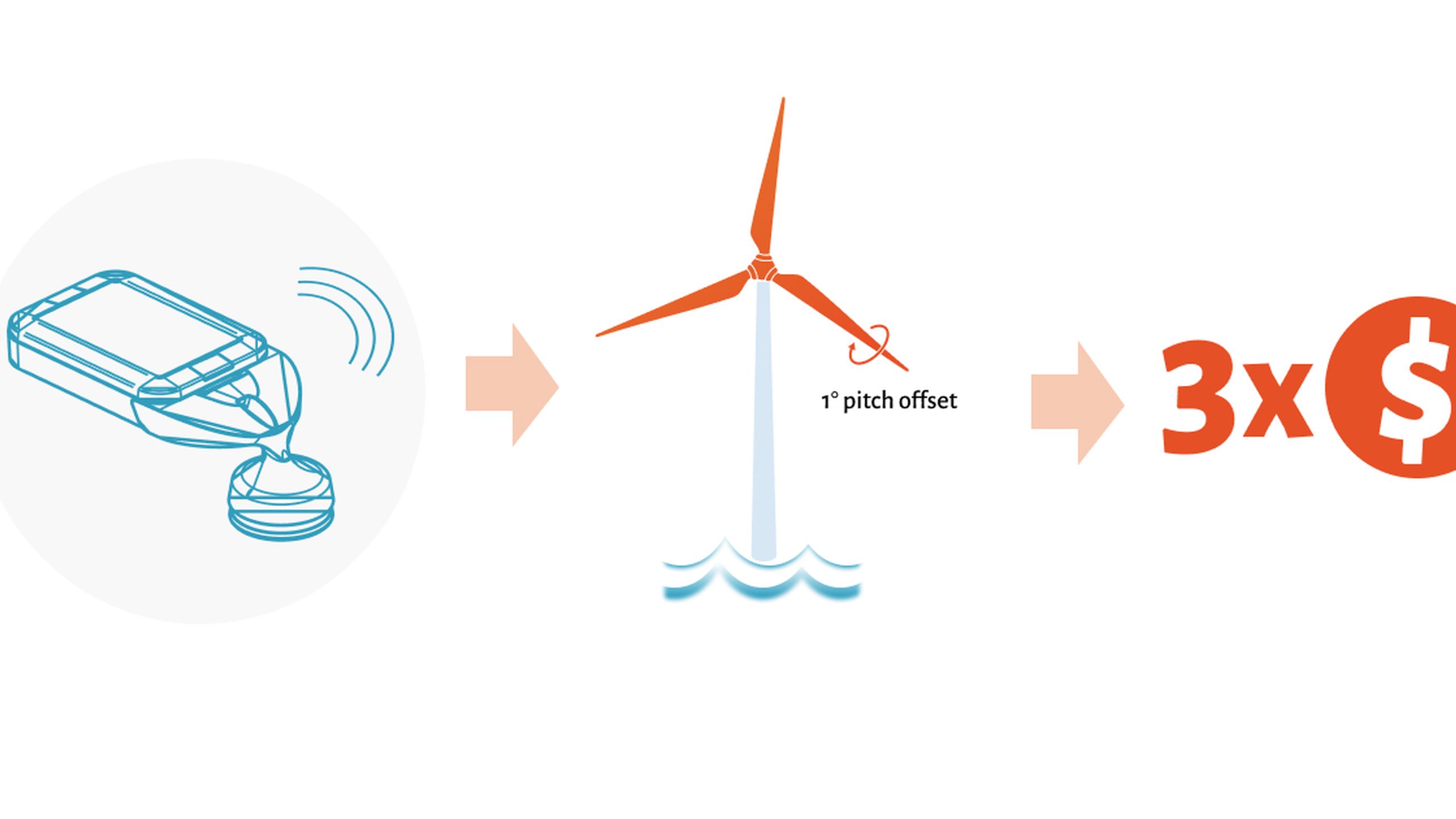

Offshore logistics are expensive and complicated, therefore having an additional remote monitoring system can help in targeted areas. When underperformance appears, Windfit can find the cause faster than having to do site visits or inspections. In the Nord Sea we have helped our customers detect and monitor the causes of underperformance in some of their turbines. A very high aerodynamic rotor imbalance was detected by Windfit throughout the winter, indicating that the real issue was not just a misalignment of the blade, but a dynamic error of the pitch system.

The returns of using Windfit on an offshore wind farm are much higher due to the higher capacity factors and the larger size of the turbines. A 1% AEP increase on an offshore turbine could result in threefold revenue increase compared to onshore.

Today Windfit has been installed on offshore turbines as far as 180 km from land, showing how adaptable and flexible our technology is. This summer we have been equipping a wind farm with EWE, growing our offshore wind presence.