As a wind farm owner or operator, achieving optimal energy output from your fleet of wind turbines is a top priority. However, despite best efforts, production losses can occur, leading to decreased revenue, especially when compared to the expected budget of wind farms. In this article, we'll explore the root causes of production loss in wind turbines and provide insights on how to mitigate them.

Root causes of energy production loss and how to mitigate them

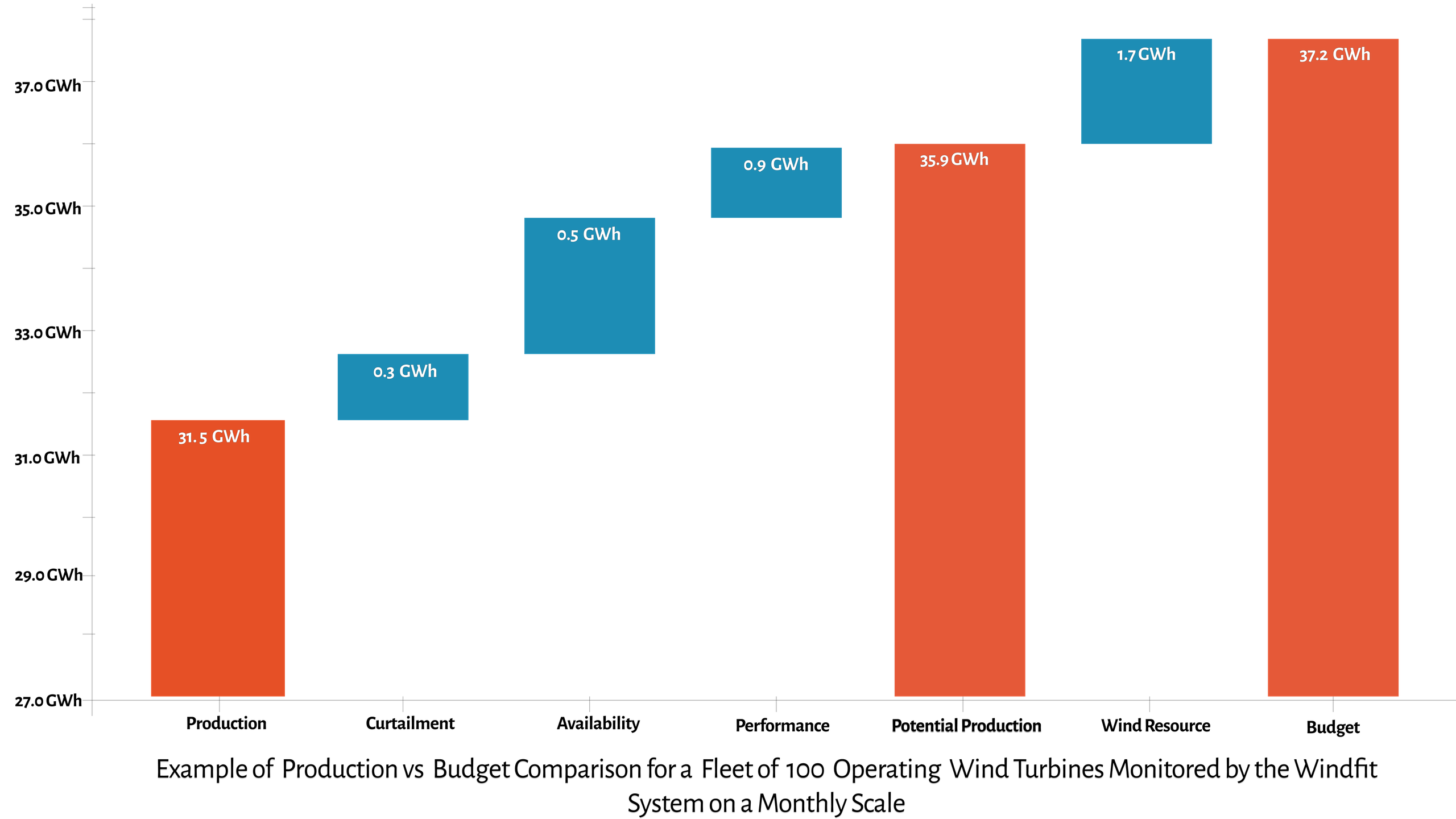

There are a large variety of issues that can lower energy production on a wind asset, but generally, they can be classified into four main categories: Availability, Curtailments, Performance, and Wind Resource.

By monitoring and addressing issues related to these categories, you can maximize the output from your fleet of wind turbines and minimize production losses.

Turbine Availability

Turbine availability can be expressed as the ratio of time that a wind turbine is operational and producing power - compared to the total time it is expected to be available for operation. It also can be expressed in terms of produced energy compared to expected energy production.

Detailed monitoring of the turbine's time and energy availability is crucial for managing wind assets at scale. Maintenance activities, turbine stops, and component failures are common issues that impact this key parameter.

Curtailments

Curtailments also known as turbine power limitations refer to imposed partial or total power reduction, due to grid, icing, turbulence, sound management, and other environmental constraints. Curtailments can be a significant source of production loss especially if they are not optimized or applied accordingly with the expected power limitation plans. Power limitation plans are quite specific to each wind farm making them difficult to monitor at scale.

Performance

Performance in the wind industry is the amount of energy that wind turbines are able to produce for a given wind speed. When turbines present a lower-than-expected performance it naturally implies a lower energy production for the wind resource that was available.

Factors such as environmental conditions (air density, turbulence), turbine defaults (pitch offers, yaw misalignments), and incorrect control parameters can result in underperformance, causing energy production losses of up to 5% of the assets' annual energy production.

Wind Resource

Wind Resource refers to the quantity of available wind energy that could be harnessed by a wind asset over a period of time. The wind resource is often compared to reference values defined before the wind farms' installation. A lower-than-anticipated wind resource will produce a correspondingly lower energy yield.

Differences in wind resources can either be punctual (less windy period) or systematic (poor initial wind resource assessment) which often accounts for some of the most significant differences between an asset’s budget and actual production.

Key Takeaways for Wind Asset Production Optimization

As presented, production differences in wind assets can be caused by a variety of factors. To maximize the output from your fleet of wind turbines, it is crucial to identify and mitigate these factors proactively. By conducting a thorough availability, performance, and wind resource analysis, investing in advanced monitoring and control systems, and taking measures to mitigate the effects of environmental factors, you can minimize production loss and ensure maximum output from your fleet of wind turbines.

Sereema Team