Tech

Maximize the Value of Your Diagnostics with the Windfit AEP Calculator

To help you better quantify the impact of operational decisions and diagnostics, …

The AEP Calculator enables you to objectively validate performance changes by comparing corrected power curves before and after operational adjustments, thereby translating diagnostics into a measurable energy …

Read MoreTech

How Nordex Owners Are Increasing Their Yield in Just Months

Wind farm owners today are under pressure to maximize every kilowatt hour of production. For Nordex turbine operators, the challenge is even more specific: understanding fleet behavior …

Read MoreTech

Legacy vs. Modern Turbines: What We’ve Learned from 200 Turbines: (2 MW vs. 4 MW Fleets)

With rapid advances in wind turbine technology over the past decade, we wanted to see how those improvements translate into real-world performance. To do this, we compared …

Read MoreTech

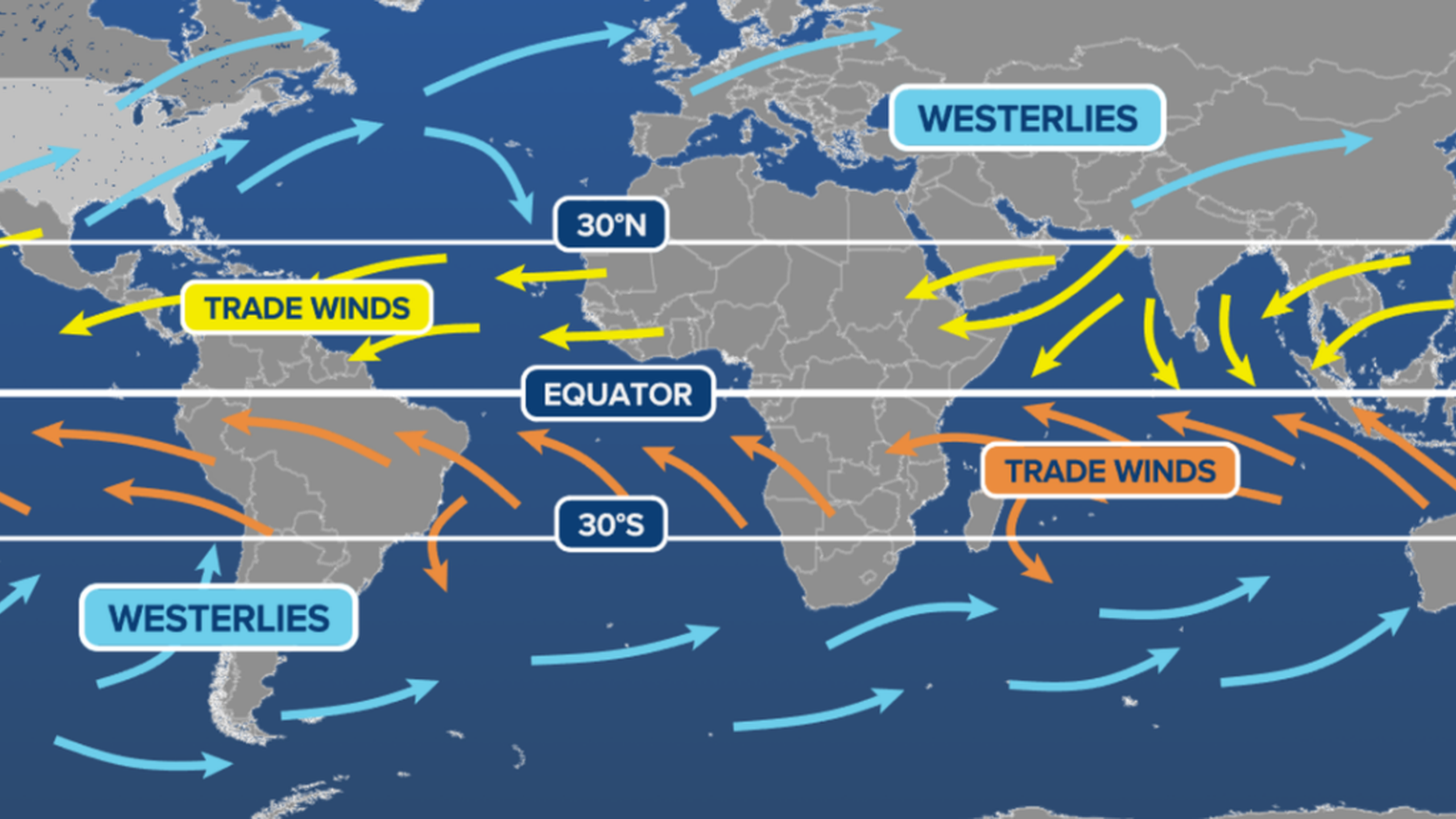

Wind Direction Mystery Revealed

In our recent LinkedIn post, we challenged readers to guess the location of a wind direction pattern. If you’ve made it here, it means you’re curious to …

Read MoreTech

One Fleet, Many Rules: Mastering Maintenance Across Multiple OEM

Running a wind portfolio with turbines from multiple manufacturers can be a real headache. From our experience monitoring over 1,900 turbines across 137 models, one thing is …

Read MoreTech

Use Case: The Value of Turbine Control Upgrade on Wind Turbines with Data-Driven Insights

With Windfit’s granular data, the client not only confirmed the effectiveness of …

As renewable energy advances, improving the efficiency of existing wind assets has become crucial. Turbine control upgrades offer a cost-effective way to boost responsiveness, increase energy yield, …

Read MoreTech

Boosting Productivity of an Aging Wind Farm with Windfit

This use case showcases the transformative impact of the Windfit system on …

Read More